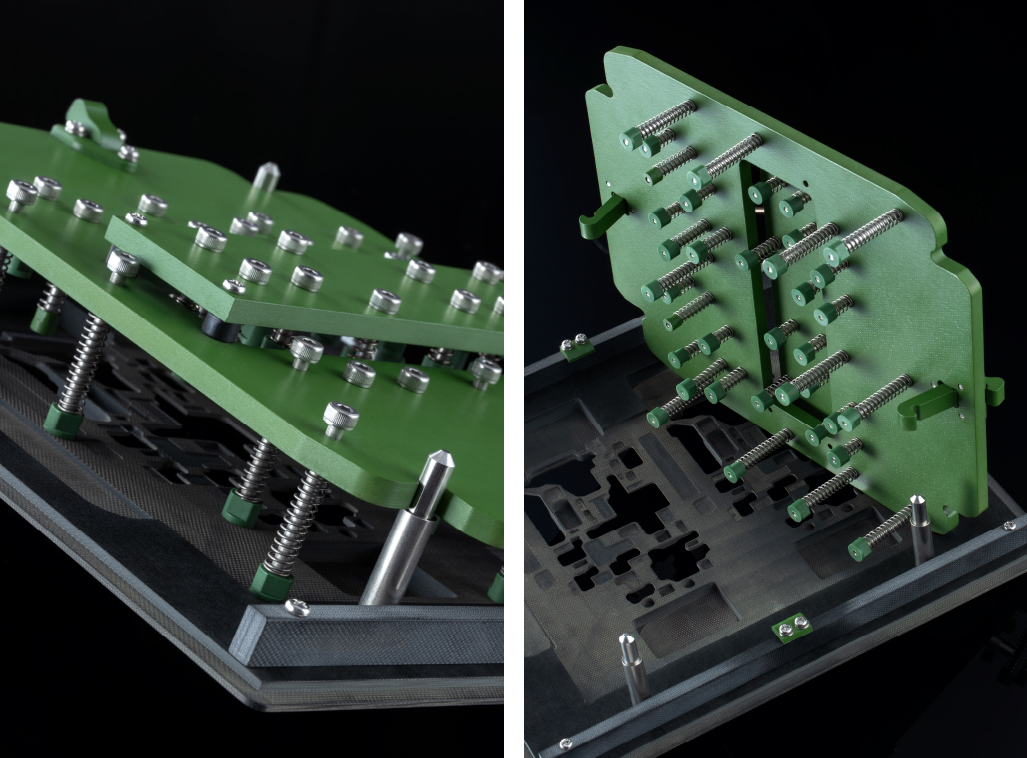

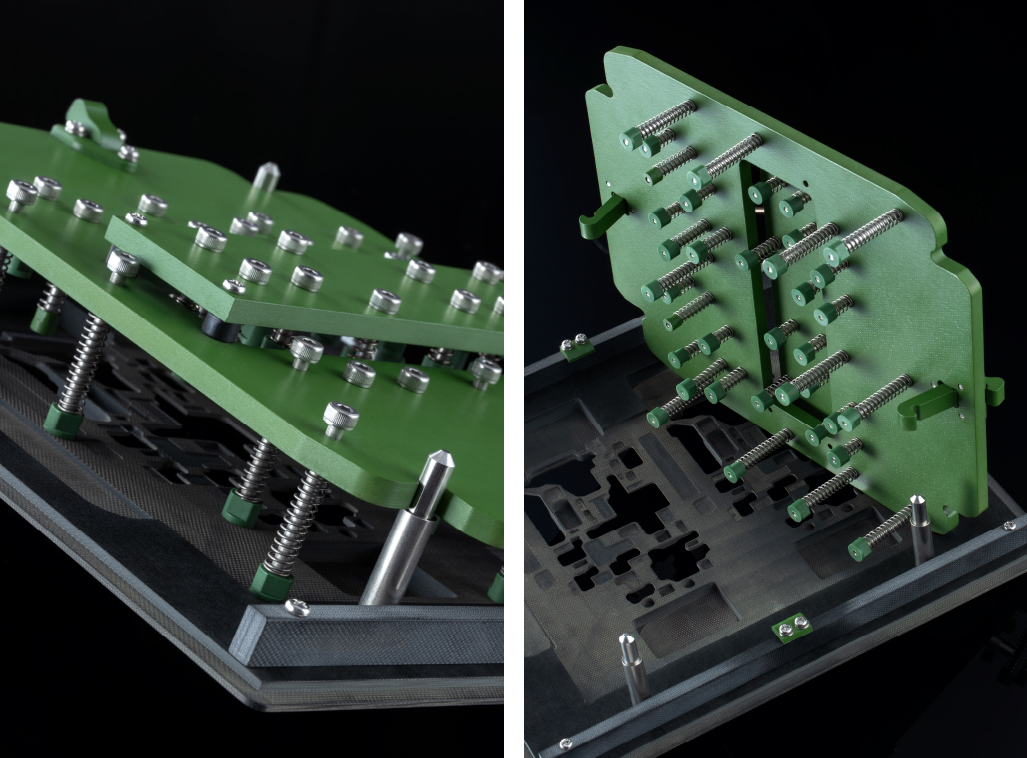

Flow Soldering jigs

We offer a wide variety of defect prevention measures, including fixing the board, preventing floating components, alignment, unsoldered parts, and bridge defects.

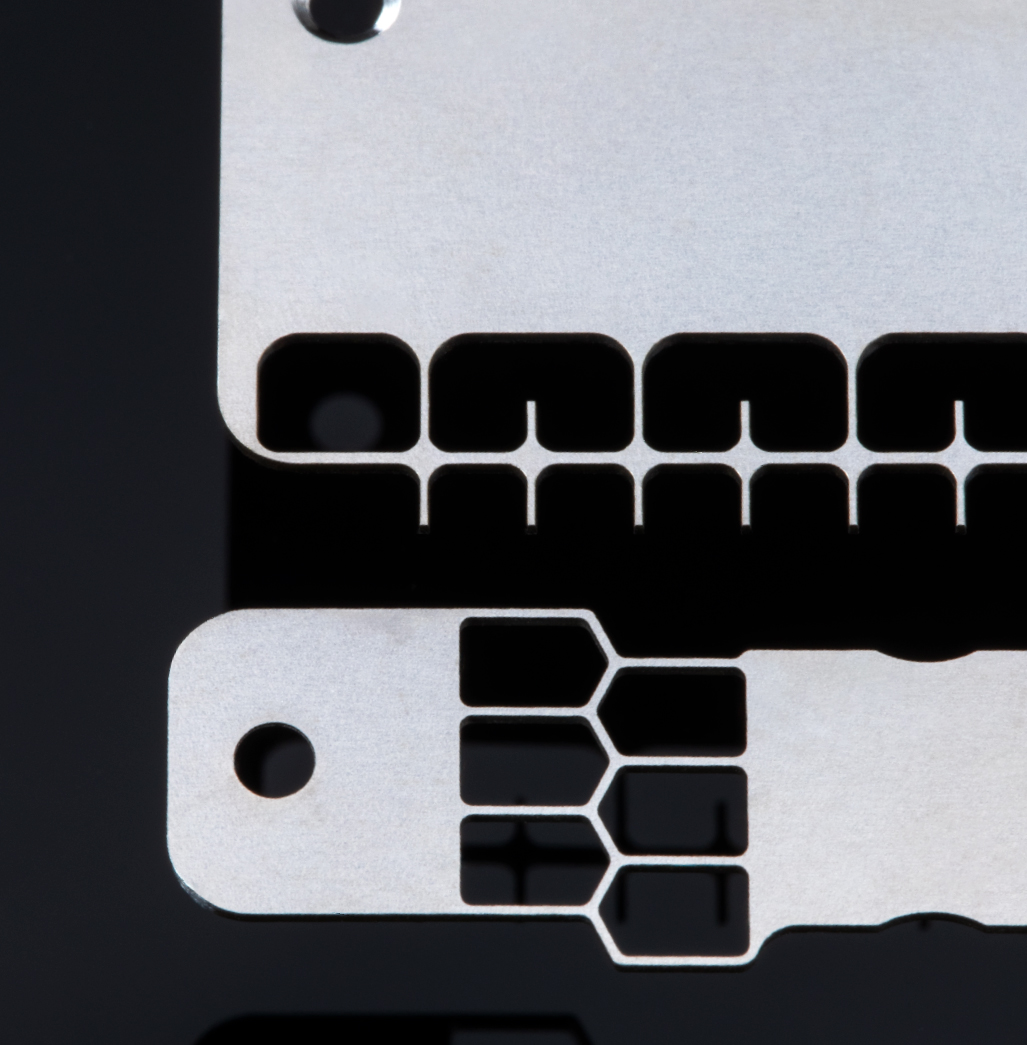

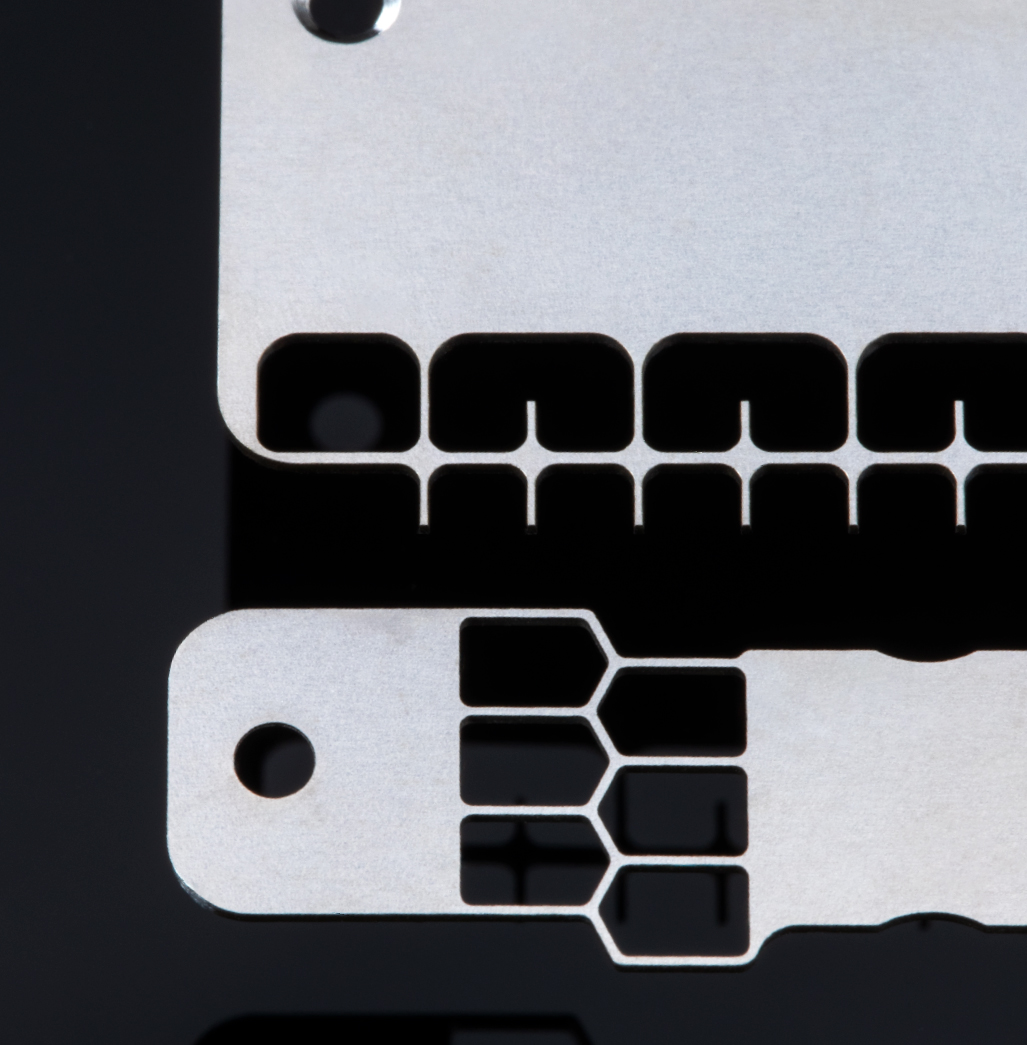

Specially processed anti-bridge plate

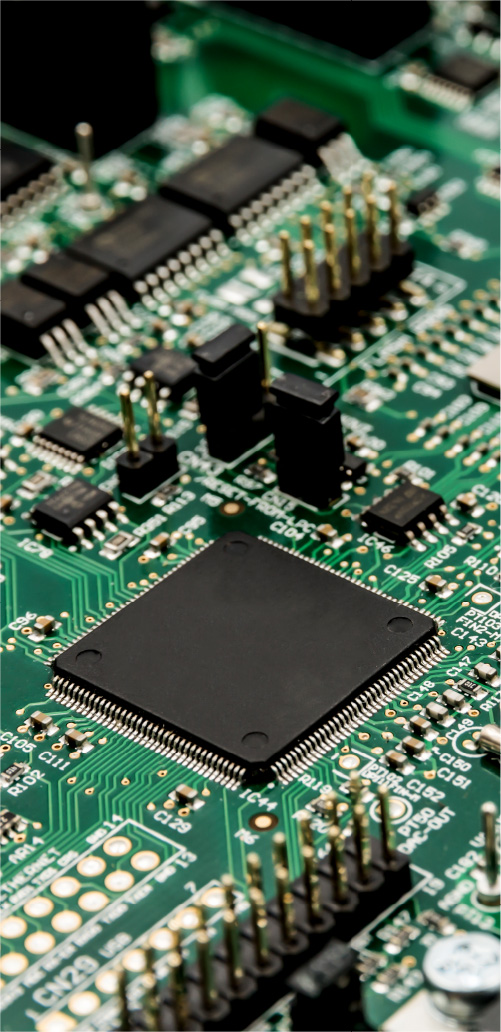

Solder Mounting Technology

We offer a wide variety of defect prevention measures, including fixing the board, preventing floating components, alignment, unsoldered parts, and bridge defects.

Specially processed anti-bridge plate

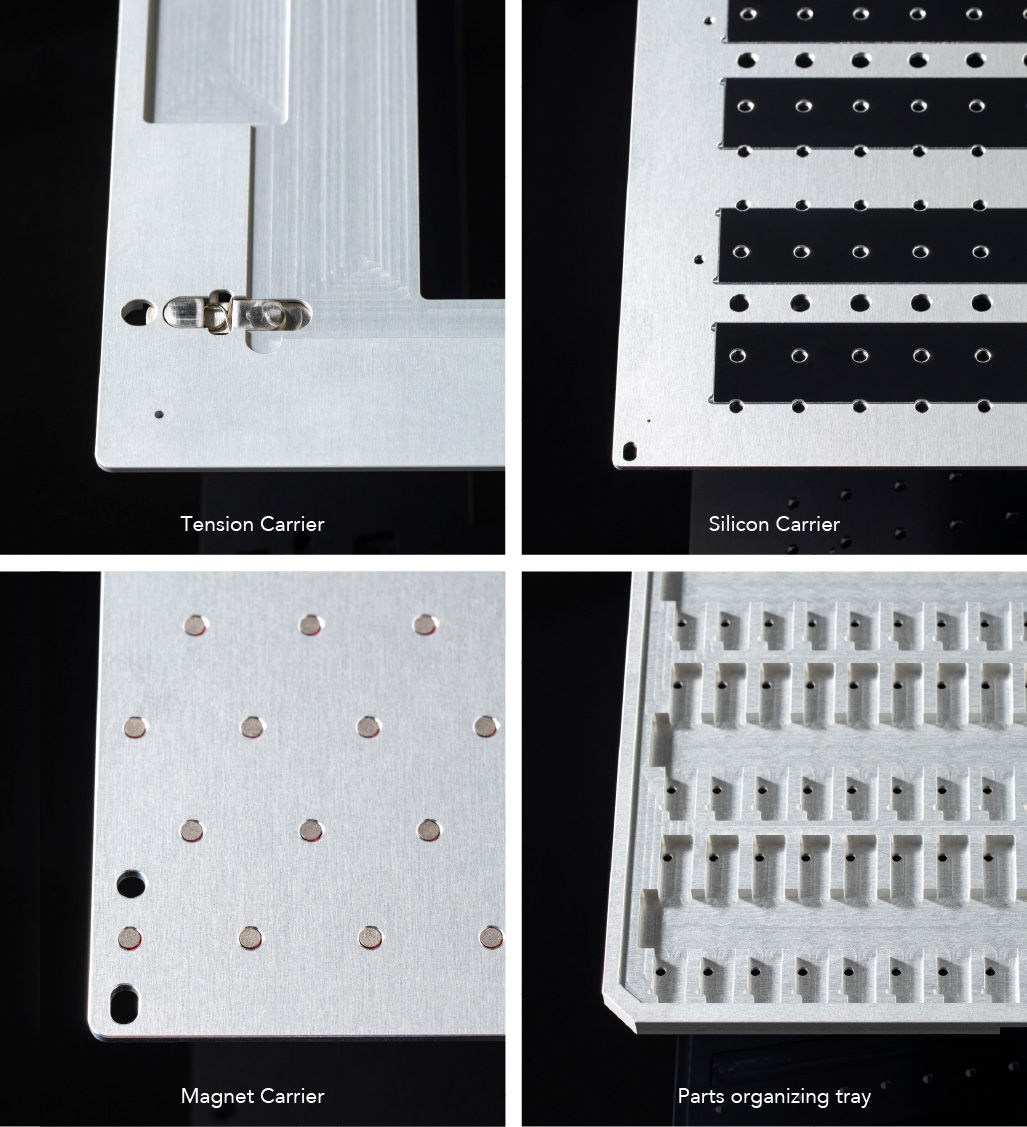

We can handle everything from thin rigid plates to thick materials with a variety of pallet types.

We fix the boards with various mechanisms such as tensile tension, silicone adhesion, and magnet retention, optimizing the mounting quality.

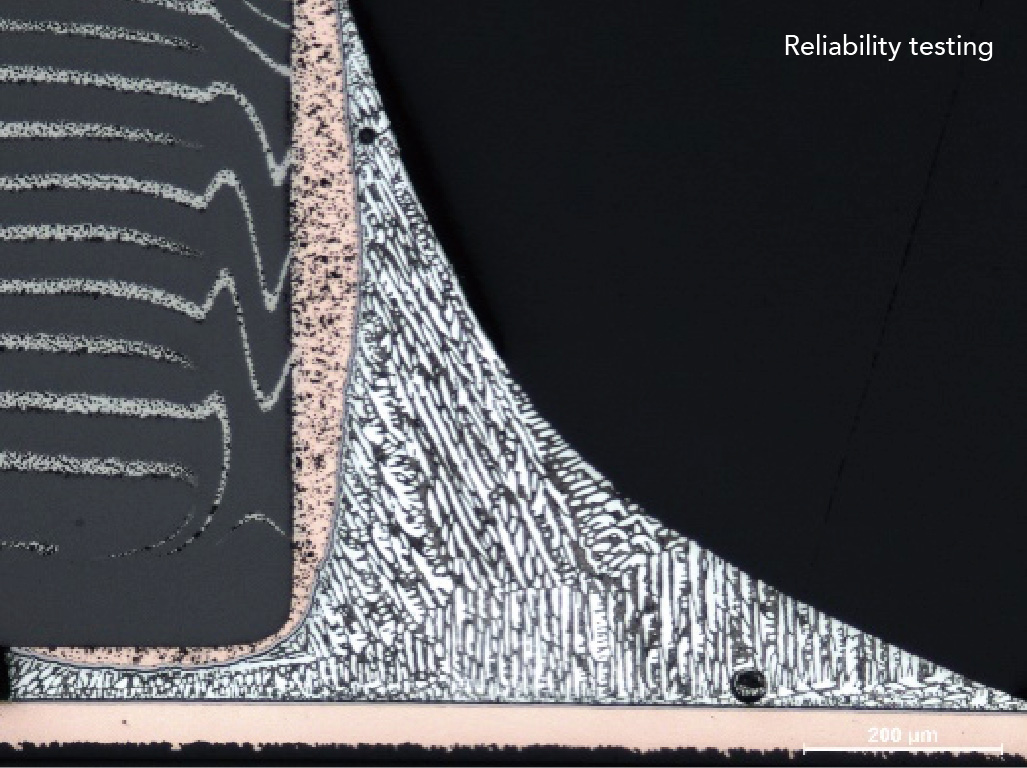

We offer a wide range of unique tests, from basic test analysis and evaluation such as cross-sectional analysis, component analysis, and various strength tests, to board warpage simulation and BGA package removal method (individual bond strength test). We also offer industry-leading equipment and expert analysis and analysis methods, and propose solutions to problems based on the results.

| test | measurement | analysis |

|---|---|---|

| Temperature cycle test Thermal shock test (hot oil) Temperature/humidity test High and low temperature storage tests Vibration/impact test salt spray test strength test Conductor peeling test Solvent resistance test Solder wettability test PCT Condensation cycle test insulation resistance test | 2/3D measurement Non-contact 3D measurement shape measurement roughness measurement laser measurement image measurement |

Elemental analysis (EDX, WDX) Auger analysis Atomic absorption spectrometry Fluorescence X-ray analysis Plasma Optical Emission Spectroscopy (ICT) FT-IR X-ray transparent observation X-ray CT observation TEM observation SEM observation FIB observation |